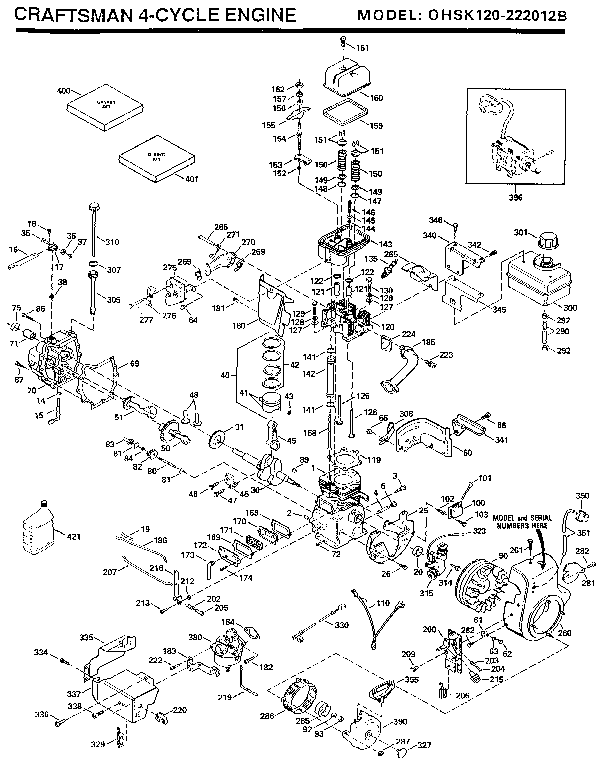

Tecumseh Ohsk120 Manual

Howdy I have this old snowblower I got from a friend, great machine, but the engine runs a bit rough, it misses every now and then, it's most visible on idle, and it backfires from time to time. The carb was leaking, so I got a kit for it and rebuilt it, now when I start the engine it goes all the way to full throttle and I can't calm it down.

There is a distributor on this machine, there are a few adjustment screws on it but I have no idea how to work this thing to get it to calm down a bit. I think it might have been heavily tampered with by the PO in order to keep it running, now putting it back might be an issue. I was wondering if anyone could point me in the right direction on how to calm this beast down and even get the throttle lever to do anything at all, right now no matter where it is set, it goes to full throttle. I can post some pics of the adjustment screws if it will help. Thanking you in advance xp. Thanks a lot 30yearTech I took the engine off the blower and took it apart.

It looks like everything is in order, the governor parts are in good shape, I must have not set it up correctly. At first sight the workings of it are a bit confusing but I think I figured it out. Now the engine misfires, and it gets worse as it warms up. From the research I've done it could be carbon buildup or spark plug. Well the exhaust valve is heavily covered with carbon, but otherwise seems fine. What is a good safe way to clean up the carbon?

Scrape off with a piece of wood? I have the engine almost fully disassembled, the only parts still together are the cylinder head and rocker box.

As soon as I have the intake valve spring off, the box will come off and the head will follow. I'd like to check this engine for proper specs all around. Thank you for the parts links, I will be ordering a few items, but out of curiosity, would you be able to recommend any parts that I should replace regardless of their condition?

So far I only have the gasket and seal set on the list, I'm thinking of ordering an extra camshaft key even though mine looks good. I don't have tools to cut valves and valve seats and I hear lapping is a waste of time, any recommendations?

I'd like to have this thing running as I will need the blower on my property. Regards and Thank you for all your help xp. Cutting or refacing the valves and seats are only required if there is damage to them. Carbon can be cleaned with a wire brush, or you can soak carbon over night with sea foam or another type of cleaner and then scrape and wipe the carbon off.

Check the valve lash on the valves. Lapping the valves will insure that there is a good seal between the valve and seat. Lapping will also aid in telling if the valve and seat are making good contact all the way around. I generally will lap the valves if I take them out for any reason. I don't have tools to cut valves and valve seats and I hear lapping is a waste of time, any recommendations?Lapping valves with the idea you will correct a non sealing seat, or one thats not concentric is a waste of time and will not work. (Firstly, this is not what it is for) I use it to mostly clean up the area after a removal and installation of valves.

Tecumseh Ohsk120 Manual

I think what you heard was geared more towards automotive engines which is almost not heard of anymore because of technology and the metals they are using. Other then that I believe 30yeartech is right. Thanks guys That is true, I heard lapping is a waste of time on automotive engines although at one point I was planning on doing it myself on a 4 cylinder engine I was rebuilding.

I took the engine apart completely, the exhaust valve was heavily coated with carbon and a collar formed on it. I cleaned it up, now it looks good as new. The exhaust valve did have some scuff marks on it on both ends, seems like lack of oil at some point, everything else looks good. The valve guides have a bit of play in them, but I don't think I want to replace them, I think they should be fine, this is not meant to be a high end engine, I just want it to run without missing. I'll be ordering a seal kit for it as it seems there are quite a few high temp orings there that I don't have, the head gasked seems like it can be reused, but the kit will come with a new one so I will replace it either way. Overall this is a very nice engine, I hope I get a lot more life out of it and lots of snow moved out of the way. Thanks guys I took the engine apart completely, the exhaust valve was heavily coated with carbon and a collar formed on it.

I cleaned it up, now it looks good as new. The exhaust valve did have some scuff marks on it on both ends, seems like lack of oil at some point, everything else looks good. Could be that carbon got down in around the stem of the valve and scratched it. If there is alot of carbon on exhaust, take a good look at your piston and rings. Sometimes this could be oil getting past the rings and burning itself to the valve. Also look at the cylinder bore, make sure it is round and isnt oblonged. This could also be from the exhaust guide being to worn allowing oil to come up past stem and burning to the valve itself.

Tecumseh Ohsk120

Thanks for the feedback DJ I ordered a kit and plan on replacing all the seals and gaskets. I think I will replace the valve guides as well if it's going to cure the missing issue. Once the new valve guides are in, do I need to cut the valves or seats, or would lapping be fine? Thank you xpLapping should be fine as long as the valve and seats are making contact all the way around. As stated in my previous post, lapping will show if there is any area of the seat that is not making good contact with the valve.

The new parts arrived, I managed to get the new valve guides into the cylinder head last night, there is visibly less side to side play with the new valve guides, I think this is a very good sign. I'll pick up a valve lapping tool today after work to make sure everything fits nicely and put the engine back together over the next few days. I hope this will have it running like new again, it would make my day for sure.

Tecumseh Ohsk120 Governor Adjustment

Would investing in a valve seat cutter and vale refacing tool be a good idea, taking into consideration that I have quite a collection of small engines, which grows every year, and that I enjoy working on them? Would anyone be able to recommend a good all around valve seat cutter/refacer for the DIY type? Would appreciate it.